- Galfan Philosophy: Right Quality - Right Time - Right Price

Electro Forged Steel Grating

What are Electro-Forged Steel Gratings?

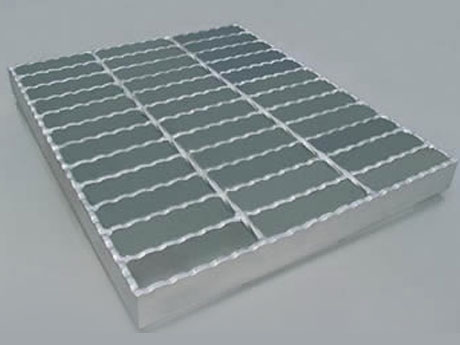

The electro-forged steel gratings are the grating panels that are manufactured utilizing the electro forging process. The electro forging process joins the cross members, the square twisted rods to the primary load-bearing bars, which are mostly made from Ms Flats. These electro forging operations are completed in the electrode forged grating welding machine to permanently fabricate the crossbars and bearings.

After the metal fabrication, the crossbars are precisely attached to the load members, projecting out of the grating top by approximately 1-2 mm. The electro-forged steel grating products will typically be produced to a standard Size up to 6000x1000mm. These grating panels are then cut to required size thereafter hot dip galvanized or Painting or self colour to meet the requirements of the customers.

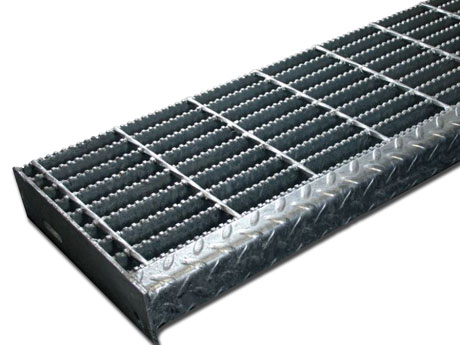

Galfan Engineers supplies electro forged grating panels, cut-to-size or custom fabricated electro forged gratings, circular gratings, heavy duty gully gratings and stair treads with required fixing clamps in Mild Steel and Stainless Steel. These gratings can be supplied in self-colour, hot dip galvanized, painted and electro-polished surface finish. The gratings are offered with plain as well as serrated bearing bars.

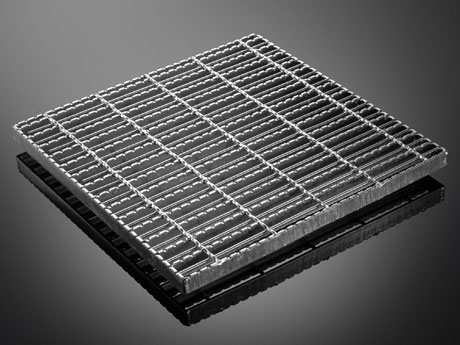

Type of Electro forged gratings

- Plain Grating

- Serrated Gratings

Standard Sizes

- Load Bearing Bar: 25x3, 25x5, 25x6, 30x3, 30x5, 30x6, 32x5, 32x6, 40x6, 40x5, 50x5mm

- Square Twisted Rods: 6mm or 8mm

Mesh Size or C/C

- Bearing Bar Mesh Size: 30mm, 35mm, 40mm, 41mm and 50mm

- Cross Bar Mesh Size: 40mm, 50mm, 75mm, 100mm

Technical Details

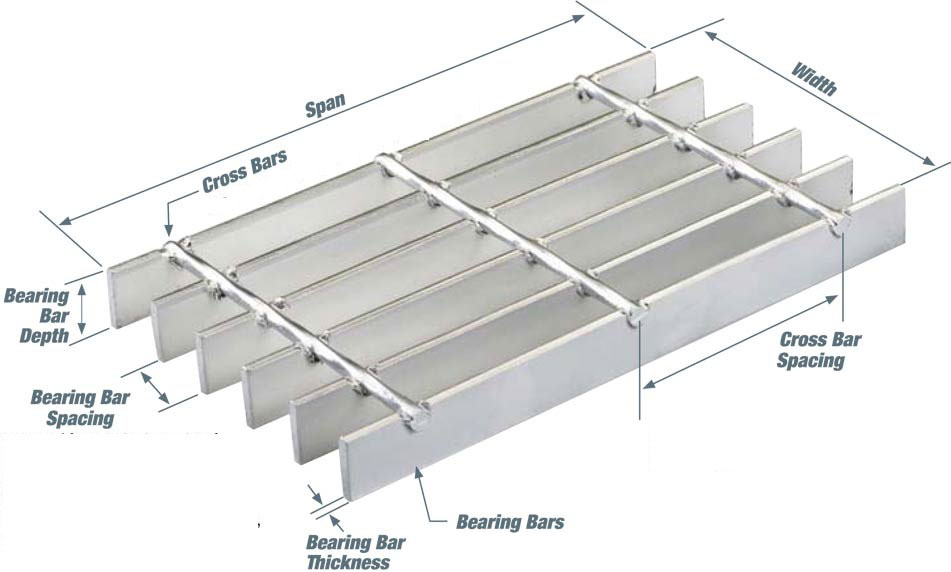

Load Bearing bar: Load-carrying main elements made from steel, aluminium or stainless steel, extending in the direction of the grating span.

Cross Bar: The connecting bars which extend across the bearing bars, usually perpendicular to them.

Frame Bar: A flat bar welded to the end of a grating panel.

Span: Direction of the Bearing bar is known as span of the gratings even if it is less than width.

Width: Direction of the cross Bars Calculated as Width of the gratings.

Mesh Size

- The distane center to center of the load bearing is called load bar spacing.

- The distance center to center of the cross bar is called cross bar spacing.

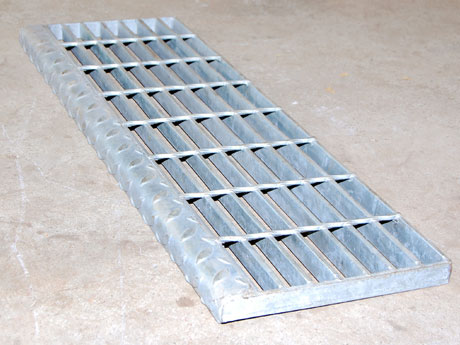

Electro Forged Step Treads

Electroforged gratings-1